Cigarticles

Trip to Camp Camacho - Part 1

February 25th at 4:45 am, we all piled into the car and headed out to JFK airport. Immediately the car filled with cigar smoke, my choice was a QdO Gran Corona since it was so damn early. We were all excited, tired and anxious to head out to Honduras that day and some even started the party early with some scotch to accompany the cigars(I passed, hadnt even opened my eyes fully yet).

After our connection in Miami we landed in Tegucigalpa, walked off the plane and entered the less the modern arrival terminal. Terry, a representative from Camacho met us at immigration and hurried us all past the lines and into the baggage claim. Terry then also got us past customs and into one of the various vans and trucks waiting to whisk us to the town of Danli in the Jamastran Valley where Camacho is located. We arrived, unpacked, washed up and after more cigars and some mojitos ate dinner. That evening though I sat with Christian over some drinks and began to ask some questions, first I wanted to know about his familys history and some background.

|

"My grandfather, Generoso Eiroa, moved from Galicia to Cuba in the late 1800's. He purchased a farm in Pinar del Rio in the 1910s; he called her "La Victoria". He died in the 1950's and my uncle and father (Generoso and Julio Eiroa) took over La Victoria for a short period of time. They left Cuba in 1959." |

The next day at 9am the trip really began to come to life.

The plantation was 2600 acres+ of luscious fields, tobacco barns, seedling huts, shade growing fields and a network of roads connecting all together. When arriving at the plantation I was in awe at not only the sheer size of it, but its lusciousness in the fields. When I asked Christian about why his family was in and or chose Honduras he replied:

|

"My father was sent to Honduras after he came back from Korea (w/ the U.S. Army) in 1962. He was then employed by The Oliva Tobacco Company (not the cigar people). Once he arrived in the Jamastran Valley, Honduras, he decided that it was the place where he wanted to stay and make his career. Angel Oliva picked the Jamastran Valley because the soil yielded full flavored tobacco and he could easily replace his Cuban tobacco supplies with Jamastran tobacco." |

Terry (our guide) took us from the seedling huts through the fields, giving us all thorough explanations about everything we encountered.

The seedlings we met were all corojo; the climate inside the hut was very hot and humid to give the plants a nice jumpstart on their way to the fields. Each little plant we saw began as 3 individual plants per holder; after the weaker 2 were plucked they allow the strong one to develop.

Each seedling hut houses approximately 85,000 plants, all tended by hand with amazing attention and care. From the seedlings we moved to some fields.

This field was being planted with seedlings that had just left the huts, each planted and watered by hand. Tobacco uses a tremendous amount of water so in between the rows of seedlings there was irrigation hard at work keeping the water flowing. Once the plants have settled into their new homes they will grow an amazing average of 2 inches a day!

To the left of the seedling field was a 3 week old(after seedling) field of Pinareno tobacco. These plants were noticeably different than the corojo we had just encountered, the leaves were delicate and somewhat soft and had a very attractive rounded appearance, in all I felt the most attractive plants to the eye. After some questions and photos we moved thru to another section of the plantation were there were some large Cameroon tobacco plants.

These plants were much taller than I.

The flowers had not yet been removed (flowers are removed to stunt the upward growth of the plant and the flowers are dissected and the seeds removed. The seeds are very small, almost like coffee grinds). The Cameroon had longer, narrower leaves, and was rougher to the touch, as well as being somewhat sticky to the hand, like resin.

We then jumped back into the trucks for a short drive to one of the many shade growing fields. Inside you felt more comfortable as the cheesecloth broke up the hot sun, also no breeze was present inside the area either.

These plants were corojo being cultivated primarily for wrapper, wrapper leaves being the most precious crop for cigar manufacturing and most difficult to grow well. The shade growing also keeps the rain off the plants; apparently tobacco plants love water but not rain (go figure), picky crops. We walked in while the plants were receiving their second clipping, essentially removing the ligero leaves (ligero means leather) which are just under the top most layer called corona.

The workers worked swiftly but with precision and care, arranging all the leaves in neat piles.

The piles are then loaded into plastic milk crates...

then the crates are loaded onto carts and pulled to the curing barns by one man in a tractor. We saw easily 15-16 barns.

The smells in the air on this plantation made my senses come alive, and also made the cigars I was smoking begin to take on a new life in my hands. I was now getting inside the cigar from its humble beginnings and respecting it far more.

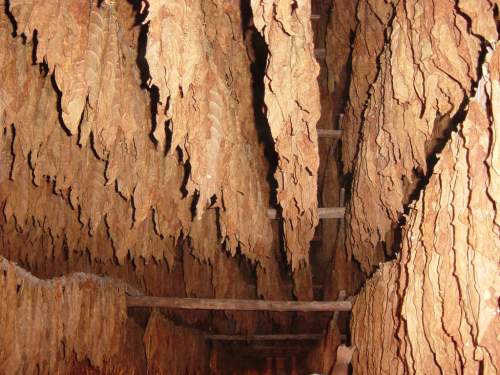

After watching the harvest we once again piled into the trucks and headed off to the curing barns. These are structures maybe 30+ feet tall and 100+ feet long, with rows of openings toward the top and shutters with long poles attached to them that act to keep them either opened or closed to help control temperature and humidity. The sides are covered with plastic and a rough burlap type material that can be rolled up the side of the barn to open it up. One small door at the end is where we entered into the first barn. In this barn they (ranch workers) were sewing together the freshly harvested corojo leaves we just saw being picked, stringing them in bunches then mounting on long poles for hanging up in the rafters of the barn.

The women doing the sewing worked very quickly, almost too fast to watch their hands. You can see the experience and skill with every stem being pierced.

The smell in this barn was that of just raw leaves, as these were extremely fresh. We walked out the door and headed down the row of barns to another barn, this one with one side already opened up.

This barn housed some cured corona corojo leaves that were just about finished. The aroma made me salivate, no joking at all.

The leaves had curled inward and turned a glorious golden brown, still soft to the touch and rather elastic as well. We passed around a bundle of leaves and I stuck my face down into the middle to get the total effect. Wowza, it was scrumptious! The depth of the tobacco scent was intense! About 2 seconds after that I lit up a Camacho corojo gigante I happened to have in my pocket; it was like a power came over me.

But that was only the beginning for these leaves. We ended our tour that day with some panoramic views of the plantation and headed back to the Rancho for poolside mojitos, more cigars, dinner and more mojitos.

Part 2 coming soon...

David Cooper hails from Long Island and has been smoking cigars for about 5 years. When not relaxing with a cigar and his french bulldog, Morty, he designs jewelry and spins music.